With the help of an accurate digital multimeter and a megohmmeter the following information will assist in carrying out primary load cell system checks either prior to proceeding with calibration of the load cells and instrumentation or to determine the general health of a weighing system.

Load cell calibration problems.

If the load cell is not calibrated it is more susceptible to every form of disruption.

To stay accurate load cells require regular calibration.

How to calibrate load cells when it comes to industrial scales one of the most important components is proper calibration.

Load cell troubleshooting begins with checking if the installation was.

If you suspect that your load cells are not performing correctly there are several common issues that might be causing the problem.

Over time load cells will drift age and misalign.

To diagnose your load cell issues consider each of the following causes individually.

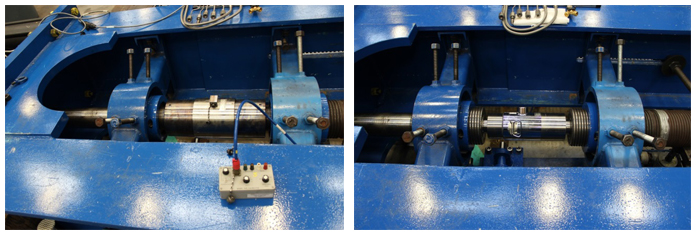

Troubleshooting guide load cell checks.

If these are unsuccessful call the cell manufacturer sooner rather than later for a more precise inspection and conclusion.

A regular maintenance schedule is the best way to stay on top of necessary maintenance.

Therefore they will need to be calibrated regularly to ensure accurate results are maintained.

Unfortunately the process to calibrate most scales is arduous and complicated which can spell significant revenue loss for growing companies.